Nekuvandudzwa kwesainzi yemazuva ano uye tekinoroji, zvinhu zveinjiniya zvakanyanya nekuomarara zvakanyanya zvinoshandiswa, nepo tekinoroji yekushandura tekinoroji haina hunyanzvi kana haigone kugadziridza zvimwe zvinhu zvekuomarara zvakanyanya.Coated carbide, ceramics, PCBN uye zvimwe zvakaomesesa maturusi maturusi ane yakanyanya kuomarara tembiricha, kupfeka kuramba uye kugadzikana kwe thermochemical, izvo zvinopa zvakanyanya kudikanwa kwekucheka kwezvakaoma zvinhu, uye vakawana zvakakosha mukugadzira.Izvo zvinhu zvinoshandiswa neiyo superhard chishandiso uye chimiro chayo chekushandisa uye geometric paramita ndizvo zvinhu zvakakosha kuona kutendeuka kwakaoma.Naizvozvo, nzira yekusarudza iyo yakanyanya kuoma chishandiso uye kugadzira inonzwisisika chishandiso chimiro uye geometric paramita kwakakosha kuti uwane yakagadzikana yakaoma kutendeuka!

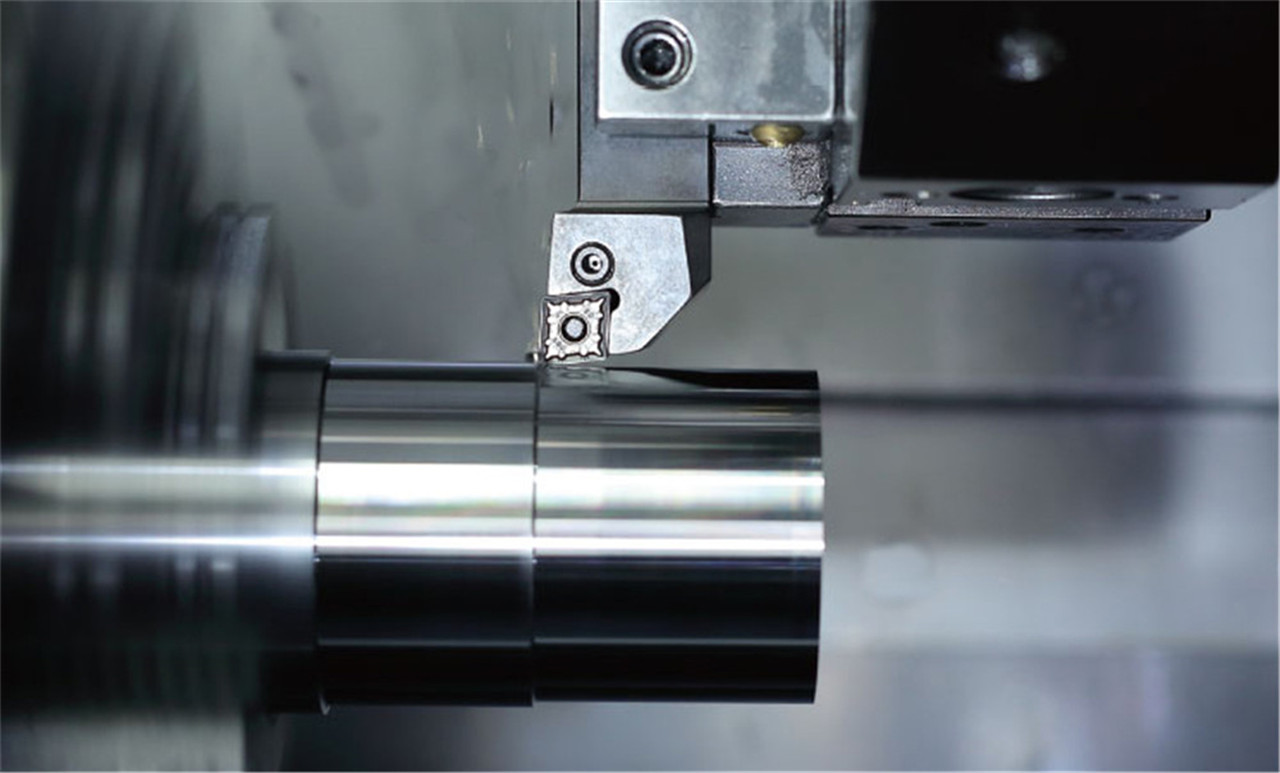

(1) Yakavharwa simende carbide

Isa imwe kana akawanda akaturikidzana eTiN, TiCN, TiAlN uye Al3O2 neakanaka kupfeka kuramba pane simende maturusi ecarbide ane kusimba kwakanaka, uye ukobvu hwejasi i2-18 μ m.Iyo yekuputira kazhinji ine yakaderera yekupisa conductivity pane chishandiso substrate uye workpiece zvinhu, izvo zvinonetesa kupisa kweiyo substrate yekushandisa;Kune rumwe rutivi, inogona kunyatsogadzirisa kupesana uye kunamatira mukugadzirisa kwekucheka uye kuderedza chizvarwa chekucheka kupisa.

Kunyangwe PVD coating inoratidza akawanda mabhenefiti, mamwe machira akadai seAl2O3 nedhaimani anowanzo kutora tekinoroji yeCVD.Al2O3 imhando yekuvhara ine yakasimba kupisa kupisa uye oxidation kuramba, iyo inogona kuparadzanisa kupisa kunogadzirwa nekucheka kubva kune chaiyo chishandiso.CVD yekuputira tekinoroji inogona zvakare kubatanidza zvakanakira zveakasiyana machira kuti uwane yakanakisa yekucheka maitiro uye kusangana nezvinodiwa zvekucheka.

Kuenzaniswa nematurusi esimende ecarbide, maturusi akaiswa simende e carbide akavandudza zvakanyanya musimba, kuomarara uye kupfeka kuramba.Kana uchitenderedza workpiece nekuoma kweHRC45 ~ 55, yakaderera-yakavharwa simende carbide inogona kuona yakakwirira-kumhanya kutendeuka.Mumakore achangopfuura, vamwe vagadziri vakavandudza mashandiro ezvishandiso zvakavharwa nekuvandudza zvinhu zvekupfeka uye dzimwe nzira.Semuyenzaniso, vamwe vagadziri muUnited States neJapan vanoshandisa Swiss AlTiN coating material uye itsva coating patent tekinoroji kugadzira mashizha akavharidzirwa ane kuoma kwakakwira seHV4500 ~ 4900, inogona kucheka HRC47 ~ 58 die steel pakumhanya kwe498.56m/min. .Kana tembiricha yekutendeuka yasvika 1500 ~ 1600 ° C, kuoma kuchiri kuderera uye hakuite oxidize.Hupenyu hwesevhisi yeblade yakapetwa kana iyo yejasi rakavharwa blade, nepo mutengo unongova 30%, uye kunamatira kwakanaka.

(2) Ceramicmaterial

Nekuenderera mberi kwekuvandudzwa kwekuumbwa kwayo, chimiro uye kudzvanya maitiro, kunyanya kuvandudzwa kwenanotechnology, ceramic tool zvinhu zvinoita kuti zvikwanise kuomesera maturusi eceramic.Munguva pfupi iri kutevera, ceramics inogona kukonzera shanduko yechitatu mukucheka mushure mepamusoro-kumhanya simbi uye simende carbide.Zvishandiso zveceramic zvine zvakanakira kuomarara kwepamusoro (HRA91 ~ 95), simba rakakura (kukotama simba 750 ~ 1000MPa), kupfeka kwakanaka kuramba, kugadzikana kwakanaka kwekemikari, kunaka kwekunamatira, kushomeka kwepasi uye mutengo wakaderera.Kwete izvozvo chete, maturusi eceramic anewo yakakwira tembiricha yakaoma, inosvika HRA80 pa1200 ° C.

Munguva yekucheka kwakajairwa, chishandiso checeramic chine kusimba kwakanyanya, uye kumhanya kwayo kwekucheka kunogona kuita 2 ~ 5 nguva yakakwira kupfuura iyo simende carbide.Inonyanya kukodzera kugadzira zvinhu zvakakwirira zvekuoma, kupedzisa uye kukurumidza-kumhanya machining.Inogona kucheka simbi dzakasiyana-siyana dzakaomeswa uye dzakaomeswa simbi yakakandwa nekuomarara kusvika HRC65.Inowanzo shandiswa ndeye alumina based ceramics, silicon nitride based ceramics, cermets uye whisker toughened ceramics.

Alumina-based ceramic maturusi ane yakakwirira tsvuku kuomarara pane simende carbide.Kazhinji, kuchekwa kwekucheka hakuzobudisi deformation yepurasitiki pasi pemamiriro ekucheka-kumhanya, asi simba rayo uye kuoma kwakaderera.Kuti uvandudze kuoma kwayo uye kupikisa kuramba, ZrO kana TiC uye TiN musanganiswa inogona kuwedzerwa.Imwe nzira ndeyekuwedzera simbi yakachena kana silicon carbide ndebvu.Pamusoro pekuoma kwakatsvuka kwakanyanya, silicon nitride based ceramics zvakare ine yakanaka kuoma.Kuenzaniswa nealumina based ceramics, kukanganisa kwayo ndeyekuti zviri nyore kuburitsa tembiricha yakakwira kana uchigadzira simbi, iyo inowedzera kupfeka chishandiso.Silicon nitride based ceramics inonyanya kushandiswa kutenderedza nguva nenguva uye kugaya grey cast iron.

Cermet imhando yecarbide-based material, umo TiC ndiyo chikamu chikuru chakaoma (0.5-2 μm) Iwo akasanganiswa neCo kana Ti mabhainda uye akafanana necemented carbide maturusi, asi ane hukama hwakaderera, kukweshana kwakanaka uye kwakanaka. kupfeka kuramba.Inogona kumira tembiricha yekucheka yakakwira kupfuura yakajairwa simende carbide, asi inoshaya kupikisa kwecemented carbide, kuoma panguva yekucheka kunorema uye kusimba pakumhanya kwakaderera uye chikafu chikuru.

(3) Cubic boron nitride (CBN)

CBN ndeyechipiri chete kune dhaimani mukuoma uye kupfeka kuramba, uye ine yakanakisa tembiricha kuoma.Kuenzaniswa nekeramics, kupisa kwayo kwekupisa uye kugadzikana kwemakemikari zvishoma zvishoma, asi simba rayo rekuita uye anti-crushing performance zviri nani.Inoshandiswa zvakanyanya pakucheka kwesimbi yakaoma (HRC ≥ 50), pearlitic grey cast iron, chilled cast iron uye superalloy.Kuenzaniswa nematurusi ane simende e carbide, kumhanya kwayo kwekucheka kunogona kuwedzerwa neodha imwe yehukuru.

Iyo composite polycrystalline cubic boron nitride (PCBN) chishandiso chine yakakwira CBN yemukati ine kuomarara kwakanyanya, kunaka kupfeka kuramba, kusimba kwakanyanya kwekumanikidza uye kunaka kwesimba kusimba.Izvo zvisingabatsiri ndezvisina kugadzikana kwekupisa uye kuderera kwemakemikari inertness.Inokodzera kucheka kupisa-resistant alloys, cast iron uye iron-based sintered metals.Zviri mukati meCBN zvimedu muPCBN zvishandiso zvakaderera, uye kuomarara kwePCBN maturusi anoshandisa ceramics sebhainda kwakaderera, asi kunogadzirisa kusagadzikana kwemafuta uye kuderera kwemakemikari inertia yeyaimbova zvinhu, uye yakakodzera kucheka simbi yakaoma.

Kana uchicheka grey cast iron uye simbi yakaoma, ceramic chishandiso kana CBN chishandiso chinogona kusarudzwa.Nechikonzero ichi, mutengo-kubatsirwa uye kugadzirisa kwemhando yekuongorora kunofanirwa kuitwa kuti uone kuti ndeipi yekusarudza.Kana kuomarara kwekucheka kwakadzikira pane HRC60 uye diki rekudya rinogamuchirwa, ceramic chishandiso isarudzo iri nani.PCBN maturusi akakodzera kucheka maworkpiece ane kuoma kwakakwira kupfuura HRC60, kunyanya kune otomatiki machining uye yakakwirira-chaiyo machining.Uye zvakare, iyo yakasara kushushikana pamusoro peiyo workpiece pamusoro mushure mekucheka nePCBN chishandiso zvakare yakagadzikana pane iyo ine ceramic chishandiso pasi pemamiriro eiyo imwe flank kupfeka.

Paunenge uchishandisa PCBN chishandiso kuomesa simbi yakaomeswa yakaomeswa, zvinotevera zvinofanirwa kuteedzerwa: sarudza yakakura yekucheka yakadzika zvakanyanya sezvinobvira pasi pemamiriro ekuti kuomarara kwechishandiso chemuchina kunobvumira, kuitira kuti kupisa kunogadzirwa munzvimbo yekucheka kupfave. iyo simbi iri pamberi pemupendero munharaunda, iyo inogona kunyatso kudzikisa kupfeka kwePCBN chishandiso.Uye zvakare, kana uchishandisa diki kucheka kudzika, inofanirwawo kutariswa kuti iyo yakaipa yekupisa conductivity yePCBN chishandiso inogona kuita kuti kupisa munzvimbo yekucheka kunonoke kupararira, uye nzvimbo yekugera inogona zvakare kuburitsa pachena simbi inopfavisa mhedzisiro. kupfeka kwekucheka.

2. Chimiro cheblade uye geometric parameters ye superhard tools

Kutsunga kunonzwisisika kwechimiro uye geometric parameters yechishandiso chakakosha zvikuru kupa kutamba kwakazara kune kucheka kushanda kwechishandiso.Panyaya yekusimba kwechishandiso, simba repi rekushandisa reakasiyana blade maumbirwo kubva kumusoro kusvika pasi nderokutenderera, 100 ° dhaimondi, sikweya, 80 ° dhaimondi, katatu, 55 ° diamondi, 35 ° diamondi.Mushure mokunge blade zvinhu zvasarudzwa, chimiro cheblade chine simba guru chichasarudzwa.Mashizha akaomarara anofanirwawo kusarudzwa akakura sezvinobvira, uye rough machining inofanira kuitwa nedenderedzwa uye hombe tip arc radius blades.Iyo tip arc radius inenge 0.8 pakupedza μ Zvinenge m.

Machipisi esimbi akaomeswa matsvuku uye akapfava maribhoni, ane brittleness hukuru, ari nyore kuputsika uye asina kusunga.Iyo yakaomeswa simbi yekucheka nzvimbo ndeyemhando yepamusoro uye kazhinji haiburitse chip accumulation, asi simba rekucheka rakakura, kunyanya iyo radial yekucheka simba yakakura kupfuura iyo huru yekucheka simba.Nokudaro, chigadziro chacho chinofanira kushandisa nzira isina kunaka yepamberi (enda ≥ - 5 °) uye yakakura kumashure (ao = 10 ° ~ 15 °).Iyo yakakura deflection angle inoenderana nekuoma kwechishandiso chemuchina, kazhinji 45 ° ~ 60 °, kudzikisa kutaura kwechishandiso uye chishandiso.

Nguva yekutumira: Feb-24-2023